The fossil fuel pricing increased in the past 24 months. There a couple of reasons for this increase. The producers see no competition and set prices as they wish. Probably production difficulties due low reserves or high demand low supply. However, global climate change from millions of tons of CO2 into atmosphere from fossil fuel is another pressure to reduce operation and attain friendly applications and usage. The gloomy picture by climate change heightened the threat. These pressures are against fossil fuel further developments and there is generally a reduced use of fossil fuel.

Biofuel development sets in, market and usage, widespread awareness. Monopoly shaked and price dipped very low since August 2008. The competitor-Biofuel, benefitor-People. Oil producers are making lose since then while trying to scare biofuel off the stage.

The biofuel development has taken leap. First generation was food based-Food to fuel collects a lot of critics due to land clearing and changes in biodiversity, micro climate change and high food prices. Second generation, billions invested in non food land crops like grasses, jatropha. Food chain dislocation avoided but major issues of land and water use. The third generation biofuels are sustainable-not a food crop. Such include algae sequestrating CO2, minimum land use converting even waste to biofuel.

With the first generation biofuel such as from cassava, corn soya sugar cane there are impacts that needs attention. They are food based, expect related food products, other related derived products will directly increase in price. Beside high operational cost the final product price will expect high price from consumers. This cannot be affordable by consumers which makes the project not feasible and competitive. Cassava needs more land, fertilizer while it takes minimum of 6 months for maturation. Processing to biofuel will incur high operational cost either.However,PNG has so much idol lands/wasteland and as claimed to be rich we can accommodate cassava.

Corn, soya beans and sugar cane have the same implications and benefits. While Oil palms have option to extract residue oil and convert them to biodiesel to reduce operational cost to maintain competition their main products.

The second generation of biofuels is non- food such as jatropha. The food debate stops here but land ,space will hang on and keep operational cost higher. In both first and second generation biofuel both do not solve climate change with CO2 emissions but adds more. When more land is cleared ,plants are removed and such CO2 is accumulated. Soil erosions, change in mineral composition and long term changes in biodiversity. However, agricultural knowledge is ours and we can solve it and go sustainable!

The third generation biofuel is more interesting. The focal focus is algae biofuel.

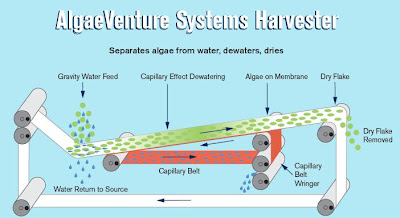

Current indications are very promising in algae. Improved technology with recent discoveries to very efficient low cost operations from growing algae to biofuels.

By comparison, the second and third generation biofuel is feasible for PNG. The need for fuel cannot be overemphasized. Given plenty of arable land in PNG, second generation biofuel plants like jatropha are vital. Markham valley given to bush fires and hunting rats and bandicoots could earn biofuel jobs and income for the locals and the nation. The are many benefits even from cassava from cost and benefits analysis. The cost of final products like biofuel can be reduced since a lot of by products can be derived beside biofuels.

Both will increase internal employment opportunities and increase over all economic activities. It is possible to employ more than >20 thousand employees from degree holders to planters and harvester. Increase to 20-30 thousand employees as industries increase permanent green jobs. Practically graduates recruiting will have deficit by numbers. If government wants to solve rising unemployment rate, crime and violence, poverty-go biofuel! If high violent and crime rate, social conflicts and clashes should be solved –engaged people in biofuel projects from energy farms to processing and distribution. Case studies from Nicaragua jatropha bears 30 kg fruits giving 18 kg /hour beans with two harvest times corresponding to flowering times. Study and practical hands on showed one ton equivalent to 70kg refined petroleum, 270 kg coke like char,200 kg ammonical water which can be used to fertilize the land again.

Besides, the following by products are available to the producer for other earnings.

Glycerine for high grade soap, seed cake for animal feed while cosmetics can be derived using 36% linoleic oil.

Cassava biofuel has similar benefits. However, may differ due to final product out put that may aid the main ethanol pricing. China, Brazil, Thailand and Indonesia are reported to produced 13,172 million tons ethanol from Cassava. Cassava is 25% convertible starch for bioethanol. While simple hydrolysis will yield more sugars for increased bioethanol –it has been identified as cheap affordable biomass for biofuel. China is producing one million tons bioethanol output from cassava along. Vehicles are already running on cassava bioethanol. China says it will produce local fuel to reduce foreign reliance on fuel while creating local employment for her people. Sen Yang, a professor from China Agricultural University, said in April that cassava alone could supply as much as 4 million tons of fuel ethanol in China.

Cassava has received much criticism about environmental impact basically more land and more fertilizer, more clearance but sustainable farming is the way forward. Even it incurred high operational cost and high energy input. However, there are inroads when all biomass are fully utilized such as gasification of other residues to produce electricity for on site energy use. Cassava leaves are high protein and very healthy diet ingredient that PNG market needs to develop. Residues from the processing starch can be make into feed as main carbon source, glucose syrups and other related products. Stalks and stems can be used to produce charcoals as fertilizer basically drought tolerant substitute while residue starch can be use to produce paper and textiles. It has high water holding capacity and supplies water to plant without wilting. The offset products and sustainable farming can greatly reduce biofuel price to make it competitive at the long run. Benefits are diverse .Increased employments and increased economic activities.

Jatropha has about 4 seasons per year resembling coffee. Has 30 years perennial life span. Contains 47.13 % crude fat convertible to biodiesel at 33% ,the rest accounts to inefficient extractions and transesterifion process. Easy to cultivate and grows rapidly. It has very high potential to go energy independence. Indian industries claimed 400 kg/ac/year in dry land at average. Currently India invested $480m in jatropha biofuel. At average one hectare of Jatropha yield 1500 L of biodiesel or above. Meanwhile there are many factors from yield to labor both human and machines. Current energy farms indicated positive progress that non food biofuel may conquer. Moreover, remaining cake is high in NPK ration plus other nutrients and fit for biofertilizer which proven applicable. Other major by products include adhesive from >38% protein content and cosmetic products including ingredients for soap. These make jatropha choice the choicest for green fuel revolution. PNG can benefit from diverse angles.

Algae biofuel is gaining momentum. Highest crude lipid content is 77% and median of 50%. Growth rate faster than banana shoot and ready for harvest within 120 hours or less than 7 days. Current developments from culturing –harvesting-extraction and utilization of biofuel from algae opened new window to abandon fossil fuel in the future.

There are many energy applications such as biodiesel, jet fuel, heating oil,plastics,solvents while the remaining biomass can yield methane, synthetic gas, hydrogen by gasification technologies, alcohol and methanol and fertilizer has being produced from one raw material-algae biomass.

Algae are 30-40 times more increased in growth rate, yield and production. At 0.15g/L /day oil yield would increased to 150 per 1000 L. Increasing at daily production would yield tons per day if hectares are increased. Aurora algae biofuel developer is selling $1.5 per gallon at the factory gate in USA. The cheapest ever! Origin oil, Exxon, BP and other giants have claimed to achieved similar or better outcomes while increased investments are reported. More than $6 billion has been invested since it came on notice.

Europe is to achieve 40% of all vehicle fuel from biofuel source one of which is algae. By year 2020 50% vehicle fuel would come from biofuel. Biofuel market is alarmingly great from local to international. Investments, developments and usage will be forced this is due to global climatic change. The threat by global climate change due to over 3 billion tons carbon dioxide emitted into the atmosphere annually.

Basically it is imperative and mandatory for PNG to involve in biofuel development since more will be emphasized on biofuel for all energy needs. It is very unwise if some one can develop biofuel from our own and monopolize local market. The choicest choice is local development to maintain local market.

Foreign investors would even wish to invest in regions where energy is cheap. With the current fuel demand increasing in the country due to rapid economic activities. Current US studies with department of energy concluded green energy jobs could create up to ten million permanent jobs. Comparatively, with more investments and developments in biofuel, PNG unemployment will be eradicated down to ten years significantly. Maintain social stability and increase living standards by margins nationwide. This is the goodness of going green. Two hundred years of going dirty fuel to self destruction can rest. The riches that once fossil fuel enjoyed will be distributed to streets and villages of PNG if we go green investments.

Depending on the carbon foot print and carbon dioxide emission and recycle, other industries can pay hefty sum such as tax to rising seal level victims. While fossil fuel developers are asked to pay, biofuels will not pay. In these centuries and beyond, fuel will not be mined but manufactured. Hundreds of years of fossil fuel gas emersions has already caused vital changes to climate, ecosystems, food chains/web, fauna and flora extinction and finally the man himself is caught within the web.