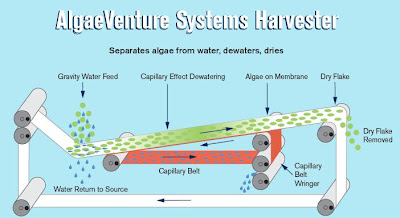

Algae harvesting,dewatering and drying technology like this may become more commercial machine for algae biofuel industries in the future.The currentsuch as by Petroalgae reviews indicating 50 grams/square meter/day continuous culture,harvesting,drying and producing biofuel can lead to marginal output per year production making algae a potential competitor for fuel price stabilization and control/demand and consumption.

The algae industry is getting there – growing, harvesting, separating and converting to useful oils is nearing completion and the ideas are proving up nicely, which should trigger competition in ideas for the process steps in controlling production costs.

Lots of claims have been made over the years for algae energy efficiency: Some experts say each acre given over to algae cultivation could theoretically produce the equivalent of thousands of gallons of oil per year, compared with an estimated yield of 18 to 335 gallons of ethanol per acre for traditional biofuel crops. Others claim that algae-growing systems could be tweaked to yield as much as 100,000 gallons per acre annually.

There are four important steps in the production of algal biofuels: growing the algae, harvesting the crop, separating the oil, and refining the oil to useful fuels. Each step in the process is the focus of intense study by scientists, engineers, and technologists across the developed world. We have already seen a very significant breakthrough in harvesting and drying of algae.

Technologists tend to overestimate what can be accomplished in two years and underestimate what can be accomplished in ten to twenty years. Algae as biofuel looks more like a ten to twenty year project. DARPA is betting on three to five years, VCs are betting on three to five years, the algae roadmap from DOE takes a decade.

A better method of making fuel from algal oil has got a lot of biofuel analysts excited;

"This is the first economical way to produce biodiesel from algae oil," according to lead researcher Ben Wen, Ph.D., vice president of United Environment and Energy LLC, Horseheads, N.Y. "It costs much less than conventional processes because you would need a much smaller factory, there are no water disposal costs, and the process is considerably faster."

A key advantage of this new process, he says, is that it uses a proprietary solid catalyst developed at his company instead of liquid catalysts used by other scientists today. First, the solid catalyst can be used over and over. Second, it allows the continuously flowing production of biodiesel, compared to the method using a liquid catalyst.

A continuous process using solid catalyst is potentially more efficient and productive, compared to batch processing. Also more scalable.

Currently, producing biodiesel from algal oil costs about $20 a gallon. But with all the attention being given each of the multiple steps in the fuel production process, some producers are projecting production costs as low as $1.50 a gallon. If costs drop that low within the next 10 years, algal biodiesel will begin to place an effective ceiling on the costs of petrol diesel. It will take time to scale up production

No comments:

Post a Comment